Upstream

To ensure the continuity and security of the supply of its reactors in France and the United Kingdom, EDF retains overall control of all operations at each stage of the cycle, through a portfolio of contacts and by stockpiling at different stages of the front-end stage of the fuel cycle (natural uranium, fluorinated enriched or unenriched uranium, and warehousing of new assemblies). Orano is an important supplier of this stage of the cycle.

Natural uranium supply

EDF’s uranium supplies are guaranteed by long-term contracts for periods of up to 20 years with a policy of diversification in terms of sources and suppliers. Indexation formulas for supply contracts include fixed prices (baseline prices that may be inflation-adjusted) and variable prices (indexed according to market price indexes). They are generally limited by floor and ceiling prices that attenuate the effects of variations in market prices on supply costs. Where necessary, the Group implements a strategy of currency hedging.

EDF is making sure to implement best practices in mineral extraction. Since 2011, EDF has conducted mine audits (2-3 a year) based on a method drawn up collaboration with the WNA (1) (see section 3.4.2.3.4 “Responsibility in the fuel supply chain”).

Fluorination (or conversion)

EDF’s needs are covered by Orano in France, as well as other international producers such as CamECO in Canada and Converdyn in the United States.

Enriching natural uranium into uranium 235

EDF meets its enrichment needs through global enrichers Orano (France), Urenco (United Kingdom, Germany, Netherlands, United States) and Tenex (Russia), primarily through fixed-price contracts.

Enriched reprocessed uranium

Since the 1990s, reprocessing has made it possible to recycle within the reactors uranium from processing spent fuel, which represents approximately 95% of the spent fuel mass. Reprocessing was suspended in 2013, pending the availability of a new industrial scheme. In 2018, the Board of Directors approved the restart of a robust, competitive and efficient sector. The first fuel assemblies are due to be loaded in 2023. The corresponding contracts were signed with the respective suppliers in 2018. Pending the effective restart of the sector, the reprocessed uranium is stored in a stable form.

Achieving significant milestones in the recovery of the sector (in particular commissioning of the TENEX residue vitrification plant in the second half of 2021 and the delivery of enriched material to manufacture a first fuel assembly) offer confirmation that all industrial, regulatory and economic conditions for the recovery of the industry have now been met.

Operating the 1,300MWe series beyond 40 years will be accompanied by industrial changes allowing the loading of enriched recycled uranium fuel into the 1,300MWe reactors, thus ensuring uranium from reprocessing is recycled over the long term.

Fuel assembly manufacturing

EDF has two sources of fuel assemblies: one is internal, via its Framatome subsidiary, while the other is external, the external supplier being Westinghouse.

Fuel supply of the two EDF reactors at Hinkley Point (United Kingdom)

In September 2016, EDF, Orano and Framatome entered into an agreement providing for the supply of uranium, conversion and enrichment services, and assembly manufacturing for the fuel supply of the Hinkley Point C reactors.

Downstream

Risks related to downstream fuel cycle are described in section 2.2.5 risk 5B “Control of radioactive waste treatment and decommissioning of nuclear facilities, and ability to meet related commitments” and 5D “Control of the fuel cycle”.

Regulatory notice

As the producer of the waste, EDF is responsible for what happens to its spent fuel and how it is processed and for the related waste, without any possibility of transfer of responsibility or limitation in time.

Orano is responsible for processing spent fuel.

ANDRA is in charge of the management of the long-term storage of final waste, in accordance with the Article L. 542-12 of the French Environmental Code.

Management of radioactive and non-radioactive waste is governed by Articles L. 541-1 et seq. of the French Environmental Code.

Processing of spent fuel from EDF’s nuclear power stations

EDF’s current strategy in this respect, in agreement with the French government, is to process spent fuel and wherever possible recycle substances: plutonium, in the form of MOx fuel, and uranium from reprocessing (see the “upstream” section of the cycle).

Some 1,100 tonnes of spent fuel are processed every year. The quantities handled are determined by the amount of recycled plutonium in reactors allowed to load MOx fuel.

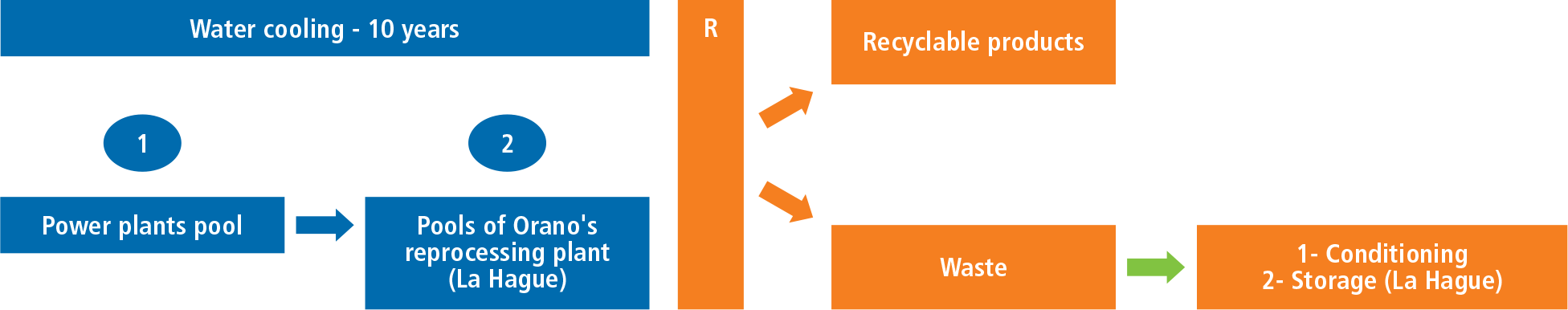

The spent fuel journey

EDF and Orano: a carefully managed partnership

Relations between EDF and Orano concern the shipment, processing, and recycling of spent fuel. The two companies have entered into a series of agreements:

-

- December 2008: a framework agreement covering the 2008-2040 period;

- February 2016: an implementation agreement covering the 2016-2023 period as well as the related supply contracts for the MOx assemblies.

EDF Pool Project at La Hague

In anticipation of the storage needs of the nuclear generation fleet, EDF is working on the design of a large spent fuel storage pool. This will make possible the long-term storage (for around 100 years) of spent MOx and ERU fuel from PWRs and from fuel assemblies of the Superphénix fast-neutron reactors, stored in the APEC (2) storage pool pending multi-recycling in third-generation pressurised water reactors, or recycling in fourth-generation (Gen IV) reactors.

(1) World Nuclear Association.

(2) Spent fuel storage pool at the Creys-Malville power plant.