3.2.3.2.2.2 Water consumption

99% of the water withdrawn is returned to the natural environment, the remaining 1% is the volume of water evaporated which, in absolute terms (324hm3), is a clear decrease of 24% compared to 2021.

3.2.3.2.2.3 Water intensity

GROUP KEY PERFORMANCE INDICATOR

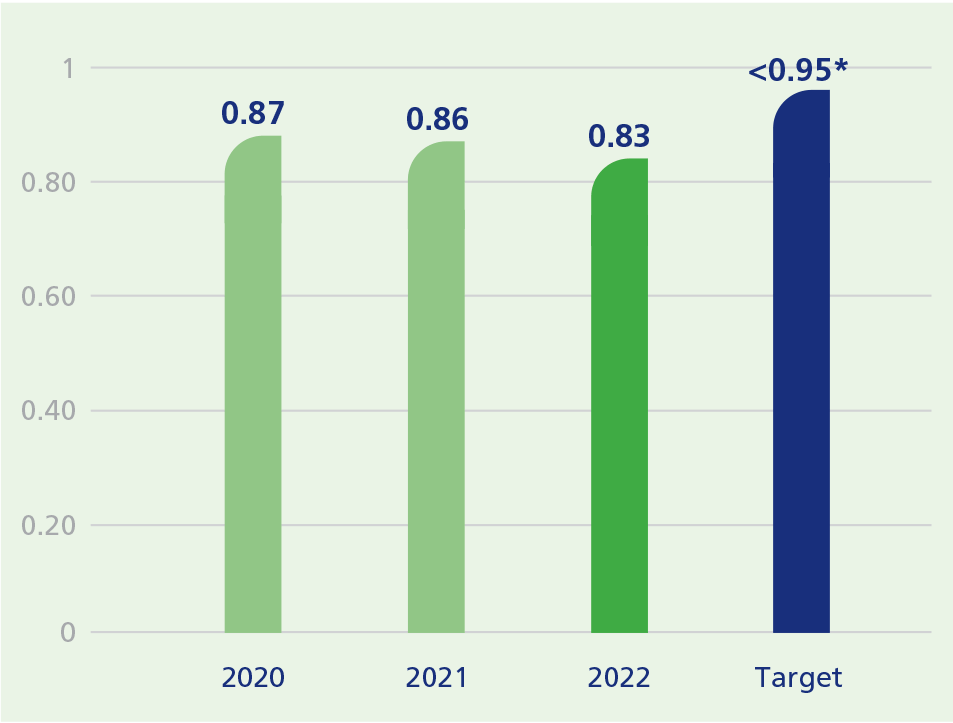

Water intensity is the specific consumption of evaporated water per kilowatt hour of electricity generated.

The stated aim is to remain below the target of 0.95l/kWh on average over the five past years, by progressively reducing specific water consumption by 2030 (the benchmark being the 2015 level, 0.96l/kWh).

Taking account of the expected variation in power generation resources and actions taken to optimise water, total Group-wide freshwater withdrawal and consumption should fall in the coming years.

The water intensity for the year 2022 alone is 0.75l/kWh.

Water intensity (in l/kWh) √

This graph shows us the intensity Water (in l/kWh) √

2020 : 0.87

2021 : 0.86

2022 : 0.83

Target: <0.95*

* On average over the past five years.

√ 2022 indicator subject to reasonable assurance audit by Deloitte & Associés.

3.2.3.2.3 Water quality and reduction of pressure on the environment (1)

3.2.3.2.3.1 Monitoring around industrial sites

EDF monitors land and aquatic ecosystem quality parameters, including subterranean groundwater around its industrial sites, particularly by measuring, controlling and analysis effluents on all sites. Monitoring the temperature of water upstream and downstream from thermal power plants (Cordemais, Blénod, Martigues) is an important parameter with regard to biodiversity. The pH of water, its conductivity, chemical oxygen demand (COD), biochemical oxygen demand (BOD5), nitrogen and phosphorus are also controlled and measured according to a regulatory environmental monitoring plan for each site. Hydrobiological monitoring is carried out each year at certain sites posing substantial environmental issues (e.g. Cordemais and Martigues) in order to ensure long-term monitoring of the receiving environments.

3.2.3.2.3.2 Specific monitoring for nuclear power plants

Each nuclear power plant has a specific authorisation defining, based on its characteristics and its environment, the water withdrawal conditions, and chemical, thermal and radioactive effluent discharge limits (mainly tritium and carbon-14). All these effluents are collected, treated, then transported to storage tanks where they are analysed, before being disposed of, in accordance with regulations to prevent any potential impact on aquatic ecosystems. Annually, more than 10,000 control analyses are carried out at each nuclear power plant, by both EDF and non-EDF laboratories. The results of this monitoring are provided to the relevant local authorities and used in documents available to the public.

There were no significant water-related environmental events or new dispute in 2022.

3.2.3.2.4 Optimising water usage

The optimisation of water used in EDF’s generation activities serves to ensure management of water resources and to honour the Group’s commitment to

guarantee multipurpose water resources (drinking water, water for irrigation, tourism, etc.) and to meet the needs of local authorities. The EDF group is working on several factors to optimise its water use and reduce pressure on the environment, by reducing its water consumption, reusing and/or recycling it, and using seawater desalination processes.

3.2.3.2.4.1 Water consumption reduction and withdrawal limitation measures

Dry air cooling systems

EDF R&D teams have designed “dry air cooling” systems for engine cooling, which reduce water withdrawal. EDF IPE’s new plants are now no longer cooled with seawater, and the same will be true for the Larivot plant. A plan for a second combined cycle power plant near Norte Fluminense is under consideration, featuring an air- rather than water-based cooling system from the design phase.

Dry cleaning of photovoltaic panels

At onshore photovoltaic power plants operated by EDF Renewables in France, rain is generally sufficient to clean the panels. However, the level of dirt and grime that builds up over the years on panels can require cleaning. Cleaning frequency may vary from plant to plant. In these cases, no products are added to the water used. Dry cleaning solutions are available and can be considered for use in cleaning panels in overseas zones facing strong water stress.

Modernising the demineralisation chain

In Angleur (Belgium), demineralised water, extracted from the River Ourthe, is used to both reduce NOx emissions and increase turbine output. By modernising the demineralisation process, the site’s water intensity has been reduced by approximately 20%.

Reducing process water needs

In Chile, following a long drought that caused the water table to fall by 1m in less than a year, specific measures were taken for the combined cycle power plant in Nueva Renca, enabling halving of process water, which plummeted from 12t/h in 2020 to below 4t/h in 2022.

(1) Regarding the regulatory framework for water quality monitoring, see the complete guide “Power plants and the environment, water withdrawals and discharges, 2020” available on the edf.fr website: edf.fr/groupe-edf/produire-une-energie-respectueuse-du-climat/lenergie-nucleaire/nous-preparons-le-nucleaire-de-demain/la-maitrise-de- limpact-environnemental-des-centrales.